Shore Power Inlet Maintenance

Keep Your Shore Power Inlet Safe (extracted from Waypoints Issue 6)

We asked our friend at the local boatyard about the most insidious electrical problem that he sees on boats. He thought about that for awhile then quickly came back with, " You'll never guess ‚ the SHORE POWER INLET!"

Why? you might ask. It looks shiny, businesslike, and made of the finest materials. True, but something inside happens, no matter how careful we are. When shorepower is plugged into AC power, current surges through the three bayonets inside the fixture. A slight amount of heat is generated from the flow of the current when the breaker is turned on and the contacts are energized. Ultimately, the heat may burn a small pit in the metal bayonets, and this decreases the area of contact slightly. Then the next arc has less area to dissipate the heat, and the small pit may enlarge from the heat, and/or a new pit develops. Sort of a growing problem. The heat builds up when on, and then cools when it's off.

Over time, the physical shape and volume of the metal bayonets may warp, shrink or change slightly. We're talking physical change so small that you'd be hard pressed to measure it, but here's where it shows up. The contact between the retaining screws inside the inlet fixture, that holds the wire tightly against a clamp, loosens slightly. Over time this may result in an infinitesimal gap between the wire and the bayonet terminal, and will cause sporadic and momentary electrical failure. This produces voltage surges or spikes to your battery charger, heaters, and any electric or electronic equipment that may be in use. Most equipment will resist damage from these momentary power spikes‚ but some may not.

Electrical equipment failures are expensive to fault-trace and expensive to repair or replace. In the worst case scenario, the electrical arcing may get hot enough to actually burn the wireends and insulation. If there are combustibles nearby and no one detects the heat, it could be even more serious! The surge or spike will be intermittent at first, possibly damaging your electrical equipment, then returning to normal ‚ as if nothing has happened. See what we mean by insidious, treacherous, secretive, mean‚ - they all fit .

How to Prevent Such Treachery

- Turn off AC power at the breaker panel by turning the master breaker and dockside circuit breaker off.

- Unplug the shore power from the boat.

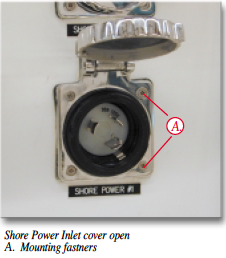

- Unscrew the four mounting screws on the outside of the fixture. If through bolts were used on your inlet, access the back of the inlet to hold the nuts from turning.

- Pull the inlet fixture away from the side of the boat, so you can get at the inside part. You may have to cut cable ties and loosen a cable clamp to free up sufficient cable to pull the fixture away from the side of the boat.

- Inspect the connector pins on the outer part of the fixture to ensure that they are not burned in any way. If burnt, this will increase the likelihood of poor contact, high resistance, and heating. Minor marking may be cleaned up with emery cloth but it is better to be safe and replace the fixture.

- Holding the fixture in your hand, turn it slightly sideways so you can see the clamping screws that hold the wires tightly in place.

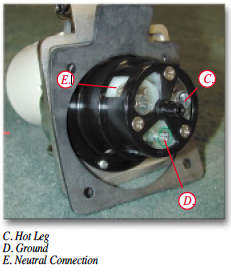

-

- Tighten them up as tightly as possible. This will squeeze the wire between the clamping plates for a renewed, excellent contact.

- Reinstall the shorepower inlet fixture to the side of the boat using sealant on the screws/bolts‚ replace any cable ties - and you're done!

Congratulations on saving yourself-INSIDIOUS FUTURE ELECTRICAL FAILURES ! Possibly you only have to do this once and find that the clamping screws are perfectly tight on subsequent examinations. Usually one subsequent tightening is all that is necessary for the life of the fixture. If you find you can't tighten the clamping screws at all, you can rest easy knowing your electrical equipment is getting uninterrupted power.